The 1980s and 1990s heralded a new chapter and era of change for the River Tees. New opportunities were emerging in the oil and gas sector, resulting in investment in new port infrastructure in Middlesbrough. Changes in legislation also gave port operators and terminals more autonomy and independence.

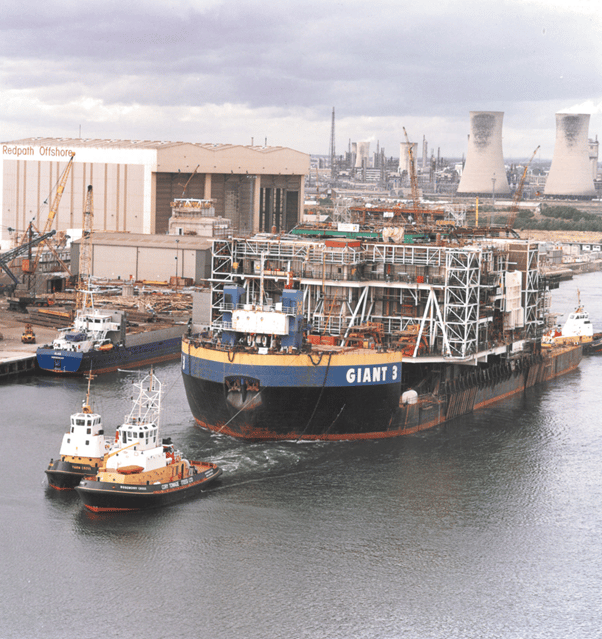

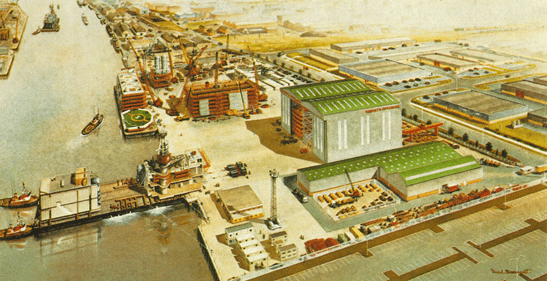

Operations at the Lin-Din Yard were further enhanced with the construction of three 42-metre high fabrication halls, designed for the assembly and fabrication of structures for the oil and gas sector.

Following decline in the British steel industry and reconfiguration of production assets, Ayrton Rolling Mills closed in 1985 and the site was purchased by AV Dawson. After an extensive programme of investment and repurposing of the existing railway structure across the site – some of which dated back to Middlesbrough’s early decades – AV Dawson’s new Ayrton Railhead was officially declared open with Minister of State for Transport Michael Portillo driving one of the company’s locomotives onto the site.

Did you know?

Decades on from his visit to AV Dawson, Michael Portillo would go on to gain global fame as presenter of BBC’s Great British Railway Journeys, which is screened in countries across the world including Australia and the United States of America.

As was the case in other areas of the country, the Tees underwent significant changes in the early 1990s owing to the process of privatisation of ports and changes to labour legislation and practices. The Statutory Harbour Authority on Tees and Hartlepool was privatised in 1992, with the original three buyers subsequently reduced to a single owner, Powell Duffryn Plc, in 1995, which later became PD Ports.

Private terminals and wharves such as AV Dawson’s site no longer had to rely on third party labour and in particular labour that was operating under restrictive employment terms and conditions. Instead, they could utilise their own teams for stevedoring work and consequently provide a more flexible and efficient service to the customer.

The oil and gas sector was experiencing strong growth at the time and as an industrial region, in close proximity to the North Sea, Teesside was able to play a key role in supporting this market.

Linthorpe-Dinsdale Yard, which was adjacent to and upriver from Dawson’s Wharf, developed a key role in the region’s proposition to the oil and gas sector. Lin-Din, as it was affectionately known, was utilised for constructing large rigs and modules, many of which were loaded onto barges for onward delivery and installation in the North Sea.

Did you know?

Over the years, the versatile 42-metre high fabrication halls have been used for the construction of oil rigs, power station control rooms and fishing trawlers as well as storing aluminium trains, and bio-secure cargoes destined for the Antarctic.